When you are processing thousands of products through your packaging line, the last thing you need is for your productivity to be jeopardized by improperly neck banded or labeled containers, or for those packages to make their way through distribution. That’s where the PDC Inspection/Rejection Unit comes in. This unit analyzes every product coming down the production line, confirming if a neck band or shrink sleeve is in the correct position on the container, before entering a shrink tunnel.

How does the Inspection/Rejection Unit Work?

The Inspection/Rejection Unit uses two types of sensors; either clear plastic visible light spectrum sensors or UV sensors, depending on the application.

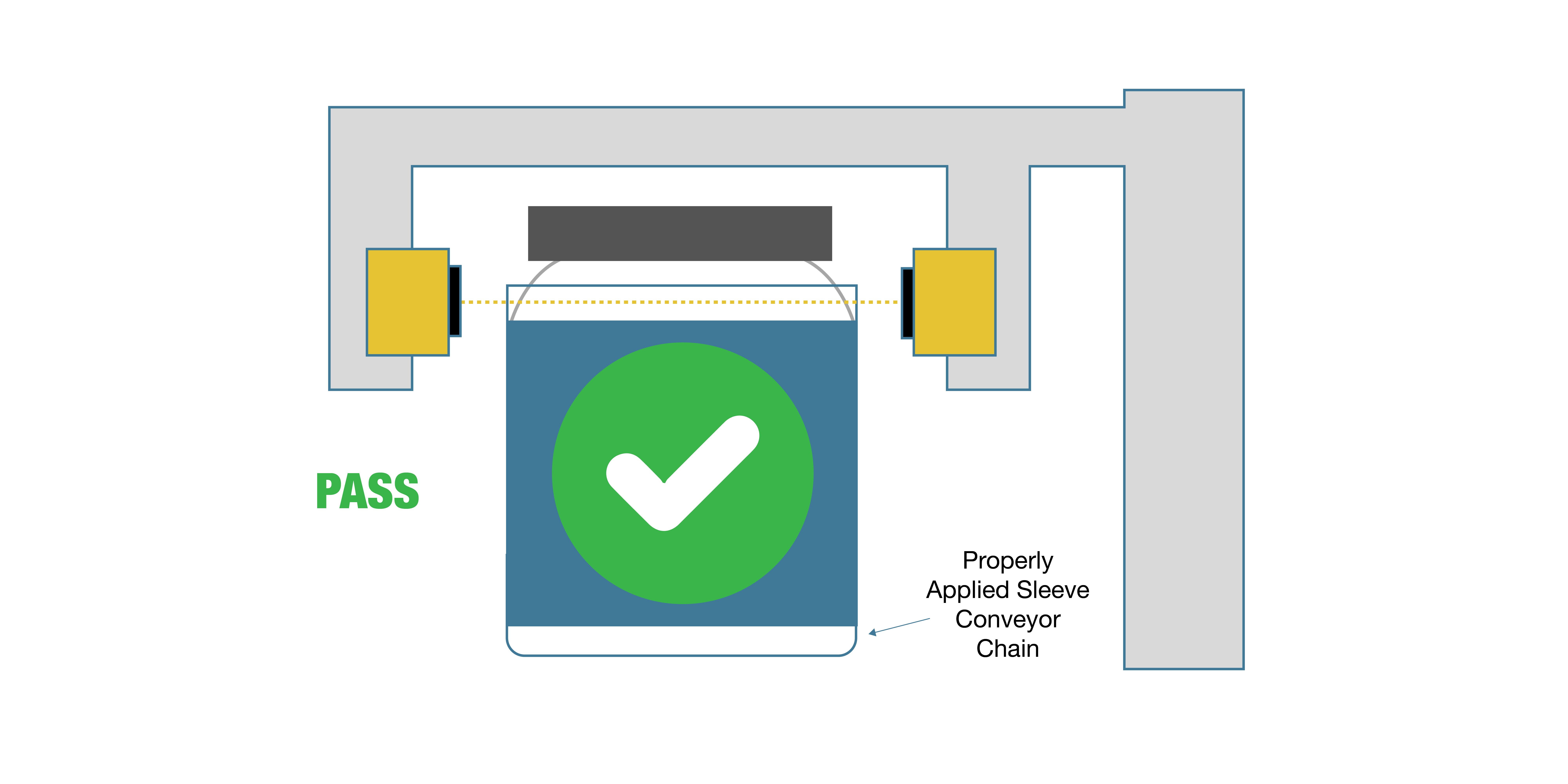

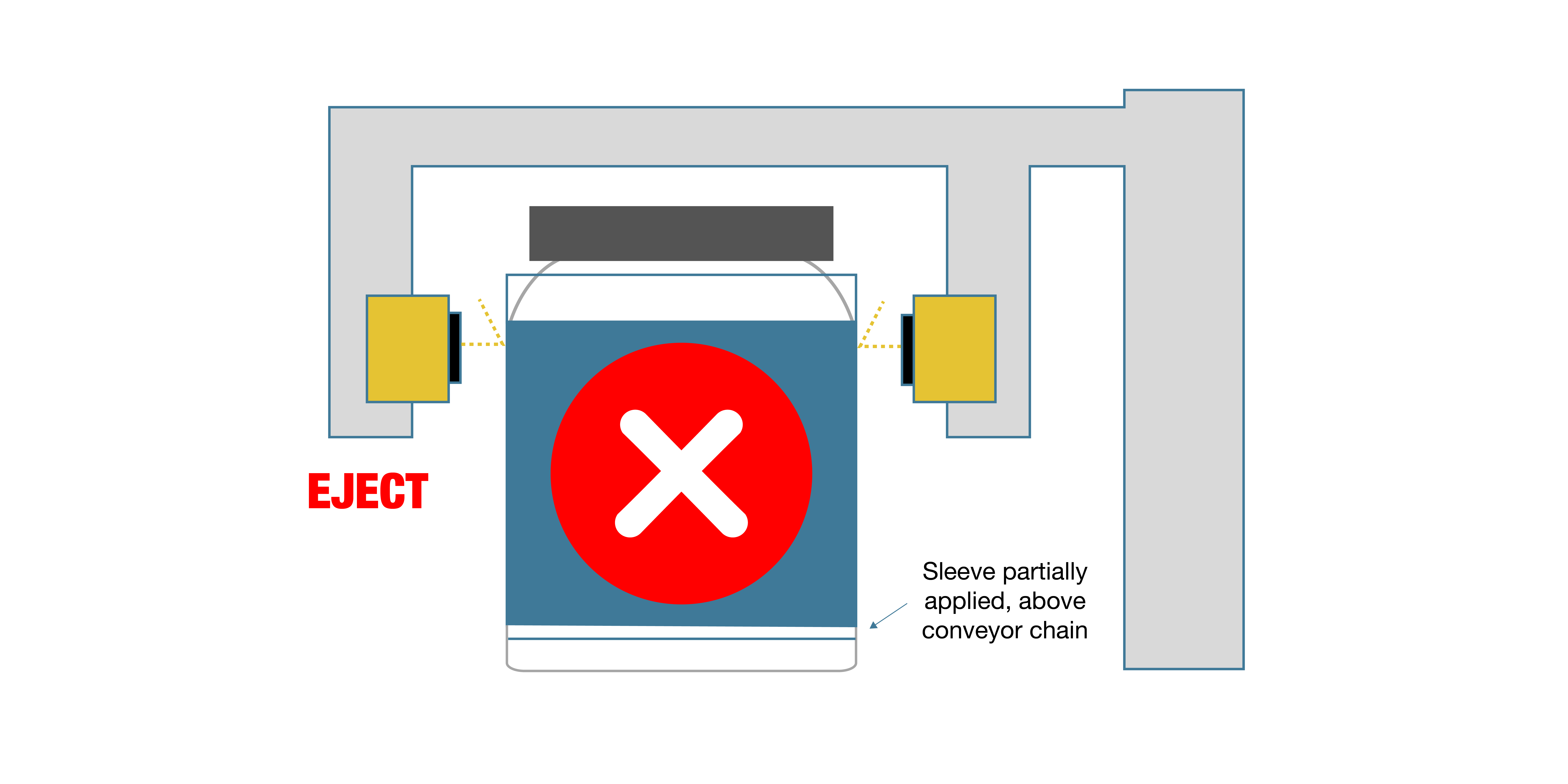

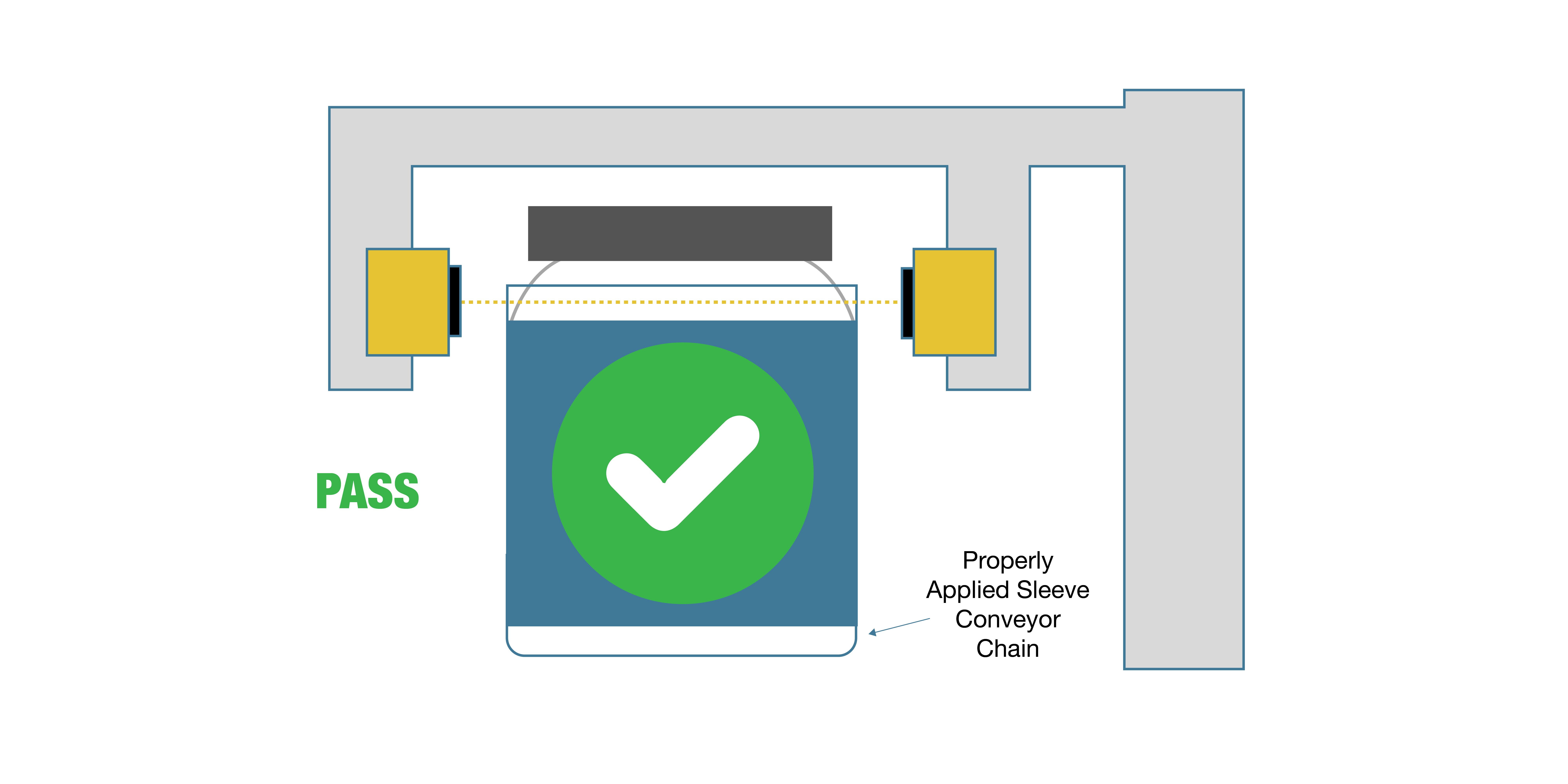

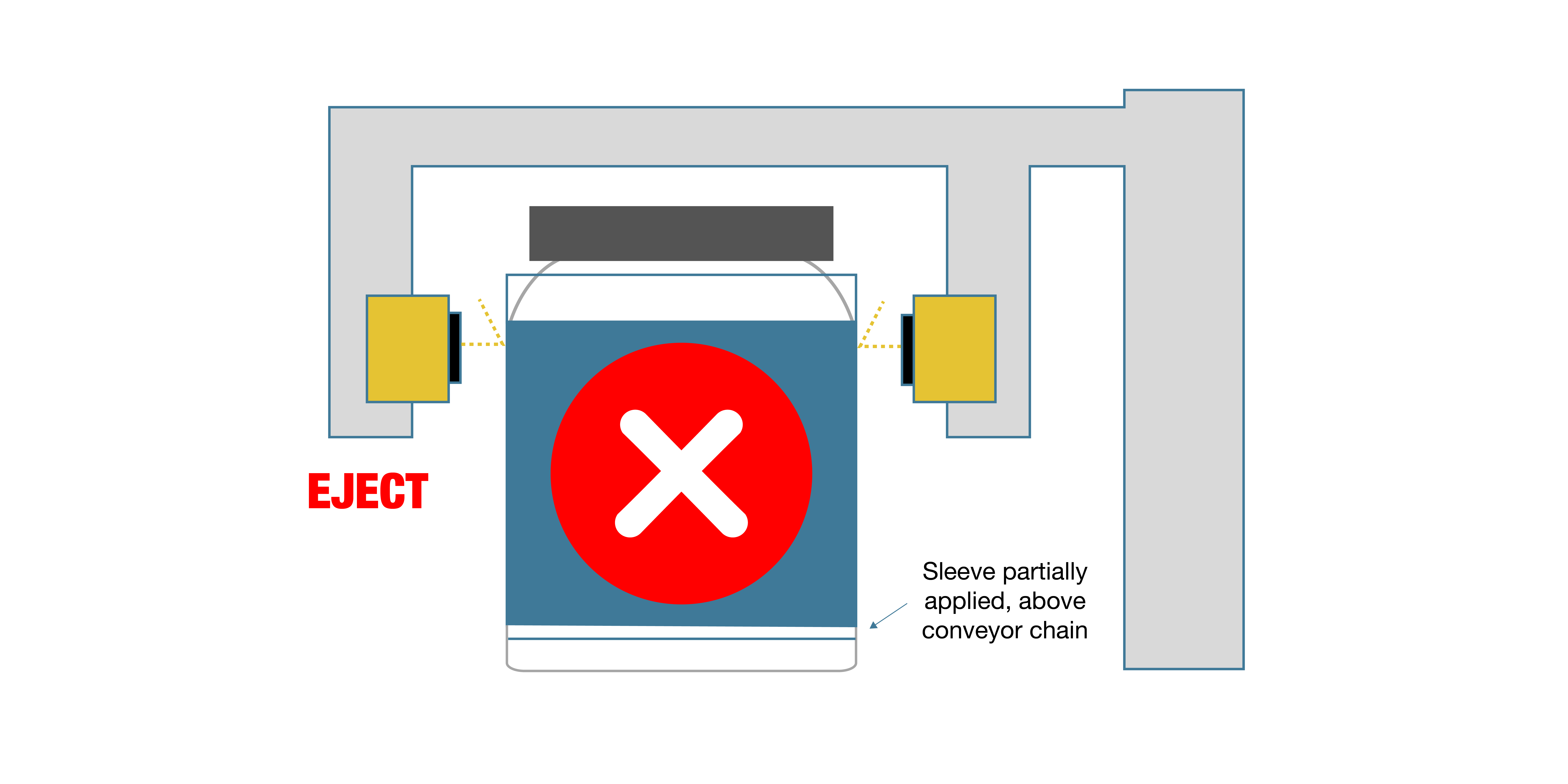

A Product Sensor turns the film sensors on. Using an emitter and receiver, the unit determines if the film is too high or too low on the container. The emitter shoots a beam to the receiver on the other side of the conveyor indicating if the band is placed correctly. Nonconforming containers are ejected off the line by a pneumatic actuator, or by a jet of air.

A standard inspection unit uses two light spectrum sensors, one above the other. If the lower sensor sees the top of the band, it lets the product pass through. If the high sensor sees the top of the band, indicating the band is placed too high, the product will not be allowed to pass. The other type of system uses UV sensors. This sensor looks for the presence of UV embedded in the film to verify the film is in the correct location on the product.

PDC’s proprietary Inspection/Rejection Unit is an optional system mounted after the sleeve applicator but before the shrink tunnel.

What types of containers can this unit be used with?

Containers of all shapes and sizes are compatible with the PDC Inspection/Rejection System. This add-on unit is designed to be adjustable! This means that operators can adjust the sensors to inspect containers of different heights.

Read about our solutions for packaging products with unique containers.

Inspection/Rejection Unit Compatibility

PDC technology is designed with flexibility in mind. This means that units like our Inspection/Rejection System are created to serve a variety of needs. This device has the versatility to:

- Connect to a PDC Sleeving Machine

- Add to your existing production line

- Operate as a stand-alone unit

Optional features which work in conjunction with your Inspection/Rejection unit includes Eject Trays or Chutes, Rotary Discharge Tables, Eject Verification, and Tray Full Sensors.

If you’re ready to reduce downtime on your production line, schedule a call to speak with one of our PDC Experts! Our team is ready to answer any questions you have and find the right solution to fit your needs.