Sleeve labels continue to take market share around the world from the “traditional” labeling technologies such as pressure sensitive and glue-applied labels. A pressure sensitive label, or self-adhesive label, is printed, laminated, die-cut, peeled off a “backing” and applied to a product. In contrast a shrink sleeve label is printed on a flexible film formed into a tube, and applied. It then reduces in size through the application of heat, conforming the label to the shape of the container.

While pressure sensitive labels are still the world’s most used label technology, there are a number of reasons why shrink sleeve labels are growing in popularity. Below we take a look at a few advantages of shrink sleeve labels versus pressure sensitive labels.

Branding

An important way to promote a product is to catch the attention of consumers on the shelf. Pressure sensitive labels can be customized for different products; however, they are limited in terms of coverage of the container. They require flat or vertical surfaces on which to adhere, limiting their applications.

Comparatively, shrink sleeves can wrap around an entire container, conforming to complex curves for a full 360 degrees, from base to the top. This allows a company to showcase its brand with full-color graphics and plenty of billboard space for messaging.

Shrink sleeving is also ideal for companies looking to do special promotions around holidays or other events with short-term graphics, or by offering products with interesting containers or eye-catching shapes.

Flexibility and Strength

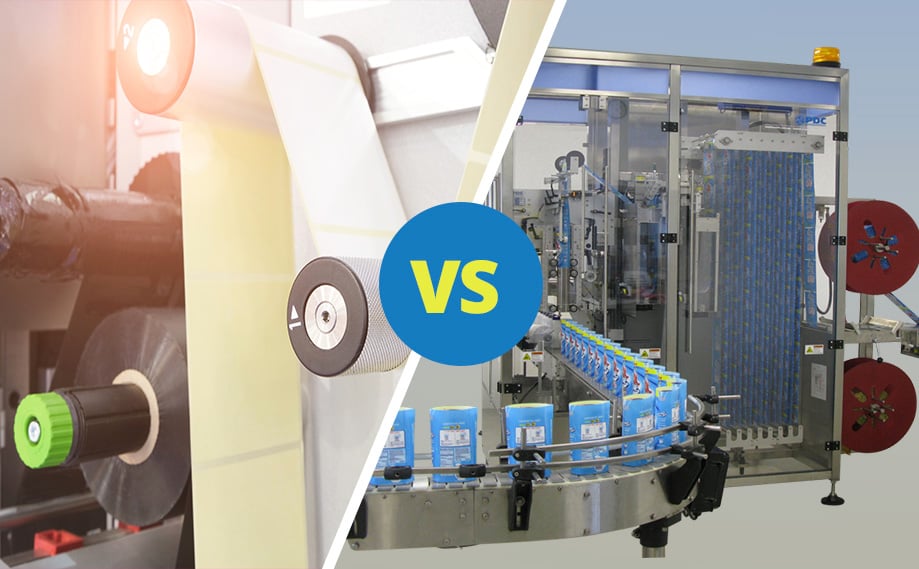

We’ve already touched on the flexibility of shrink sleeve labels, which can fit many differently shaped containers where traditionally-made product labels can’t. For example, PDC has developed custom packaging solutions for single-serve wine glasses, twin packs, and juice bottles with distinctive figurine heads, even whole garlic cloves! In addition, shrink sleeve labels are generally printed in reverse, on the inside of shrink film, protecting the graphics with clear film. This makes the label sparkle and its graphics resistant to damage from handling during transit. Shrink sleeves are also good for products that may be used in humid or moist environments, such as showers, coolers, and refrigerators. Another bonus is that certain full-body shrink sleeve labels can protect a product from UV light, extending its shelf life.

Security Through Tamper-Evident Seals

Since the 1980s and the tragedy surrounding tampered Tylenol bottles, manufacturers have worked hard at securing their products to assure the public that they are safe for consumption. For many pharmaceutical products, tamper evident packaging is mandatory due to FDA safety guidelines. Shrink sleeve labels offer a perfect solution. Shrink sleeves can easily be extended up the neck of a container and over the closure, creating a tamper evident seal. This ensures that the product is protected, has not been altered in any way and is safe to use - an important added value to the safety-conscious consumer. Tamper evident seals typically use vertical or horizontal perforations, which separate once the product is opened.

Sustainability and the Environment

There are several ways in which shrink sleeves are more desirable than pressure sensitive labels when it comes to the environment. For one, pressure sensitive labels come on a paper backing material. Once the labels are peeled off, the paper liner becomes waste. Shrink sleeve film can be made of biodegradable or environmentally-friendly recyclable materials such as Polyethylene Terephthalate Glycol (PET/PETG), Oriented Polystyrene (OPS), Polylactic Acid (PLA), and Crystallizable Polyethylene Terephthalate (CPET). In addition, because shrink sleeve labeling uses heat to apply the label to the product instead of adhesive, it can be easily removed when recycling the container, and there is no glue or adhesives in the recycling stream.

Cost-Effectiveness

In many cases, because a shrink sleeve label can cover a wide area of the container, it can perform the function of multiple labels and seals. It is often more cost-effective by reducing the steps and labels involved in production, saving time and money.

From household supplies and cosmetics to food and beverages, shrink sleeve labels are an outstanding choice for product labeling. Conforming to even the oddest-shaped containers, shrink sleeve labeling provides a 360-degree branding area and easy opportunities for tamper-evidence. The result: products that look great from top to bottom that your customers will love!

PDC has been providing U.S.-made shrink sleeving and tamper evident banding machinery and high performance shrink tunnels for over 50 years, serving a wide range of global industries from food and beverage, to pharmaceuticals and household products.

Contact us today to see how we can help you bring your products to life!