Tamper evident features and technology, as they relate to shrink sleeves may seem complex at first glance. But it is crucial to grasp these concepts for successful project implementation. To aid you in your endeavors, we have compiled a list of essential terms related to this field. By familiarizing yourself with these common tamper evident terms, you'll gain a solid foundation to effectively navigate the world of shrink sleeve labeling.

Primary Tamper Evident Terms

These terms will come up in conversations regarding the neck band or shrink sleeve label that is to be applied to your product. These phrases reference different types of tamper evident features, or components of those features, that can be utilized on your product.

Neck Bands

Neck bands are heat sealed safety features that wrap the closure and neck area of your product. Primarily used by companies selling bottled products, there are multiple functions for tamper evident neck bands. These include uses as simple as safety seals, to cover inconsistent fill lines, and as decorative neck labels with graphics.

Perforation

A perforation is a small slit or row of slits, cut into a shrink material so a part of it can be easily removed. In the case of neck bands and shrink labels, it is the feature which breaks, indicating that the product has been opened.

Vertical Perforation

Full vertical perforations are commonly used to easily remove a safety seal neck band from around the closure and shoulder of a jar, bottle or tub. Vertical perforations can also run the entire height of a sleeve sleeve label, so it can be removed for recycling.

Horizontal with Partial Vertical Perforation

Horizontal perforations, often with partial vertical perforations, are used when a full height shrink sleeve label extends up over the closure to provide tamper evidence. When opening, the consumer removes the portion of the sleeve above the horizontal perforation, exposing the cap or closure, which can then be opened. The label on the body of the package remains intact.

Tamper Evident Terms for Machines & Technology

There are a variety of different components that can be added to your shrink sleeve system to produce tamper evident features. From applying the feature itself to inspecting for any defects, these machines are integral parts of the full production line.

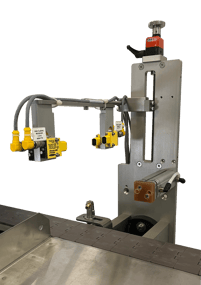

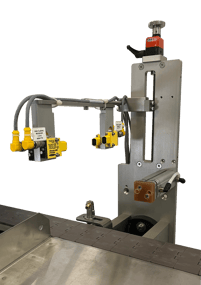

Compact Servo HPV Perforator.jpg?width=325&height=244&name=Horizontal%20Perforator%20edited%20White%20(1).jpg)

Horizontal Partial Vertical (HPV) Perforator provides tamper evidence when a shrink sleeve extends up over the closure of a package, and there is a need to tear away the tamper evidence and leave the label untouched.

Benefit: This device allows the consumer to pull the sleeve down to the horizontal perforation removing the top without tearing into the label itself.

Horizontal Perforator

This system puts consumer perforation where the closure meets the container, allowing the separation of the tamper evident portion from the rest of the shrink sleeve label, which remains on the product. The perforation can be of a range of types in terms of Cut to Land Ratio, which determines its strength and ease of opening.

Benefit: Provides a tamper evident element to a full sleeve application.

Inspection/Rejection Unit

This unit verifies the presence and/or location of a tamper evident seal or label by utilizing either the visible or ultraviolet light spectrums. Non-compliant products are moved off the production line onto an optional tray or customer-provided bin.

Benefit: Provides automatic inspection and confirmation of sleeve presence and/or placement, and greatly minimizes product that does not comply with acceptable criteria. Minimizes visual inspection and produces a higher quality product flow.

Learn more about the PDC Inspection/Rejection Unit

Pre-Shrink Unit

This unit is composed of single or dual hot air guns, wired and integrated into machine functions, which applies precise amounts of hot air at the desired temperature onto the just-applied tamper evident seal. It is used when the band and closure are larger than the body of the package and there is no natural shoulder on which the band would rest (such as banding a tapered cup and lid). The heat guns shrink the band slightly, tacking it in position so it remains in place until reaching the shrink tunnel to complete the shrinking process.

Benefit: Produces consistently positioned tamper evident seals on difficult packages.

Tamper Evident Terms for Perforation Blades

Reciprocating Horizontal Perforators

These blades are used on units like the Horizontal Partial Vertical Perforator. Reciprocating perforators have a single blade, often with a secondary “partial vertical” blade. The partial blade is often angled so that the two partial vertical perforations (often on the cap of the product) meet the horizontal perforation at a point, making it easy to pull down by the consumer from the top of the closure.

Rotary Vertical Perforators

Rotary perforators are used in continuous web flow applications, particularly on neck bands. The wheel-like blade rotates against a hardened surface on an opposing roller, such as a hardened cam follower. The sleeving material flows between the rotating blade and the backup roller, cutting the material as it is rolled through.

Tear Tab Blades or Slit Tab Blades

Available on certain models, these cut off blades produce a tab at the top of the sleeve for easy opening of the tamper evident seal.

Our team at PDC want to ensure that you have the resources to feel confident in your next shrink sleeve system purchase. For more terms and definitions, check out our Glossary of Terms on the PDC website or download our Shrink Sleeve Labeling 101 eBook using the link below.

.jpg?width=325&height=244&name=Horizontal%20Perforator%20edited%20White%20(1).jpg)